Running your warehouse efficiently is essential for productivity and profit, so here are five tips to manage your warehouse at maximum efficiency.

Use your space efficiently

According to the Guardian, using your space efficiently means that staff are more productive and there is no need to expand unnecessarily.

You can also be aware of how your space is used and stay ahead of the game by pre-empting problems. Consider using data collection to help you use your warehouse space in the best possible way. By collecting reports on shipping, the receipt of deliveries, inventories and performance, you will be able to see the complete picture; in turn, this will help you to run your warehouse more efficiently.

Be prepared

If you are already collecting data, you are on the way to being fully prepared; however, situations sometimes happen that are out of our control. Consider eventualities and draw up some procedures in case of an emergency or an incident. Use your existing data to help you predict errors that happen and think about how you overcome these issues. Whether a missing delivery or broken shelving Ireland, you will have a plan should something out of the ordinary occur.

Have back-ups available

Following on from being prepared for any eventuality, having back-ups of frequently used equipment is an excellent way of keeping your warehouse running should an accident or incident happen; for example, if your shelving Ireland collapses, keeping spare shelving Ireland, racking or nuts and bolts could keep your warehouse in business when you would otherwise have to wait days for repairs.

Back up data

Keep a spare laptop or tablet available in case your main computer crashes and back up your data regularly. Consider using cloud storage so that you can log on remotely and access everything you need to run your warehouse in the event of a system error.

Understand how your operations work

If you are collecting data, you should have an idea of how your company works; however, knowing how your data affects your warehouse is important. Familiarise yourself with your supplier and the manufactures of the essential components of the warehouse. Learn about shipping, find out about stockists, and get to know the people behind the operations who keep your warehouse running efficiently.

Embracing inclining list for your warehouse is just as essential as it is in manufacturing. The fundamental premise of inclining is only what you require, and nothing more. Feasibly lessen or removing safety stocks, and attempt to get suppliers to convey smaller quantities more often. Put in order in workstations makes better productivity because workers do not have to hunt for tools or equipment. Utilize the “5S” technique from incline manufacturing to make sure your workstations are as organized as feasible. It comprises of: Sort; Set in sequence; Shine; Systematize; and comfort — all methods planned to keep litter at bay, lessen errors, and make better the safety and organization.

Making better the warehouse efficiency is as much about usual sense and the correct storage equipment as it is about fancy selecting algorithms. Follow these easy steps and watch your efficiency soar.

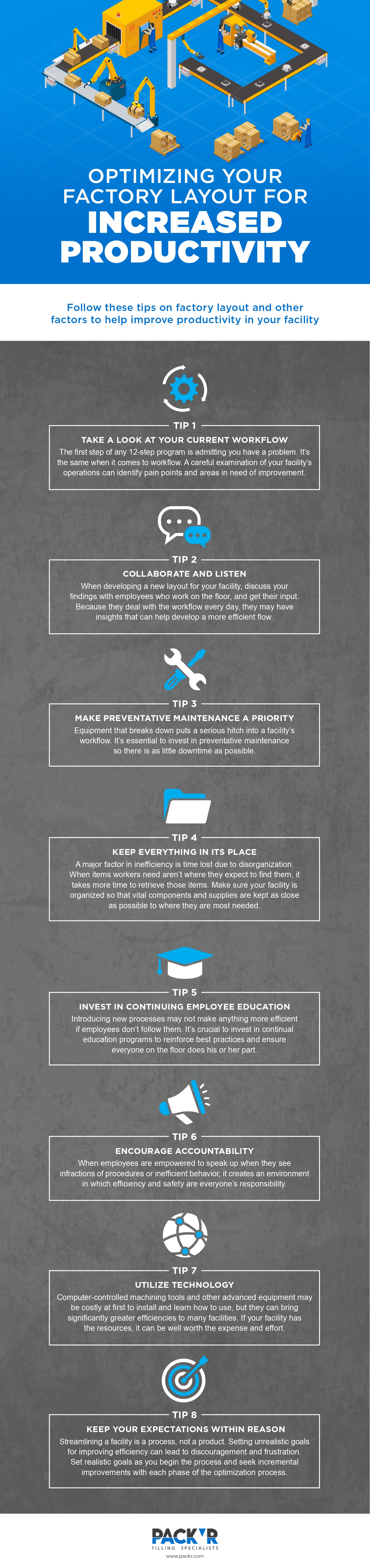

For more tips on running your faciity to its highest potential efficacy, check out the infographic below!

Infographic provided by PACK’R, a liquid filling machine company